Application

Our products are widely used in various small electric motors, smart wearable devices, precision medical equipment, household and office appliances,automotive parts and other fields.

Application

Our products are widely used in various small electric motors, smart wearable devices, precision medical equipment, household and office appliances,automotive parts and other fields.

Common Industries

Micromotor shaft can make small motor rotation, thus producing certain efficiency. For example, in the mobile phone, the vibration motor can be driven by the micromotor shaft to remind the user of the call, information and other events; In the robot, the micromotor shaft can be used to drive the movement and action of the robot. In addition, micromotor shafts can also be used to drive small fans, water pumps, retarders and other devices to achieve their specific functions. Therefore, micromotor shaft plays a very important role in small motor, and is one of the key components to realize the automatic control of small motor.

View MoreThe motor shaft is often used for vibration and operation in smart wearable devices. For example, in smart watches, the motor shaft is used to generate a watch vibration reminder, prompting the user to receive an incoming call or message. In addition, in smart glasses or headsets, the motor shaft can be used to adjust the position of the lens or screen to provide a better visual experience. In short, motor shaft plays an indispensable role in intelligent wearable devices.

View MoreMicromotor shafts are used to drive and control various mechanical and electronic components in office appliances. For example, in a printer, a micromotor shaft can be used to drive the print head horizontally to print at a predetermined position and speed; In a scanner, a micromotor shaft can be used to drive the scanning head up and down, left and right, to scan an entire document or picture; In electronic clocks and watches, the micromotor shaft can be used to drive the movement of the hands, so that the clock time is accurate and reliable. In addition, micromotor shafts can also be used to drive key components in office equipment such as folders, punches, paper cutters and label makers for automated operation and efficient production. Therefore, it can be said that micromotor shaft is an indispensable key component in office appliances.

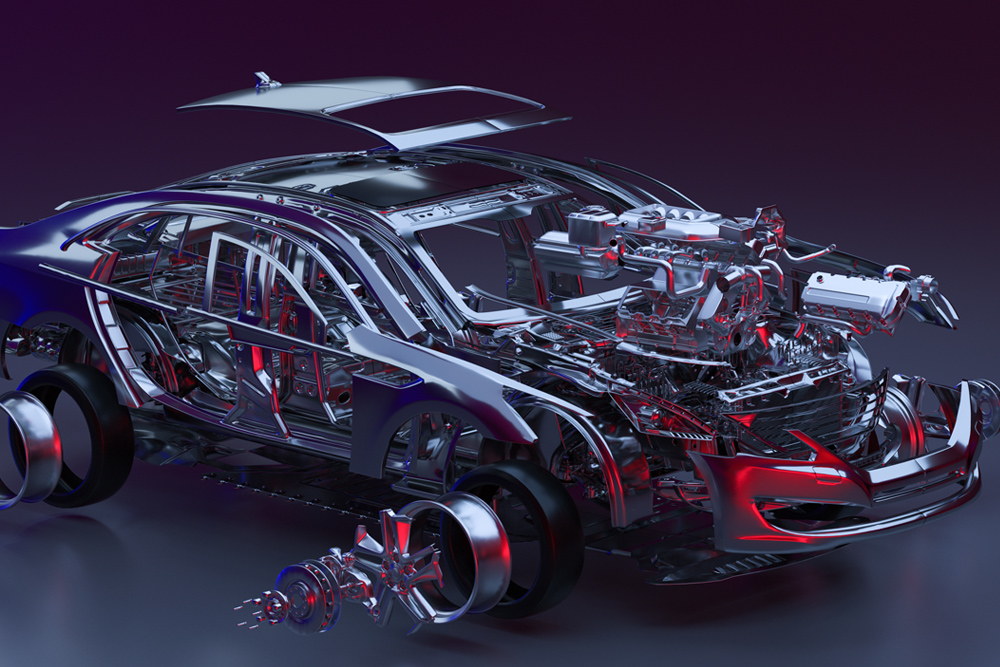

View MoreMicromotor shaft also plays an important role in automobile parts. It can be used to control various electronic devices and mechanical components in the car, such as electronic fuel injection system, air conditioning system, seat adjustment system, window lifters, rearview mirror adjusters, and so on.In the electronic fuel injection system, the micromotor shaft can be used to control the injection amount and injection time of the nozzle to ensure the normal operation of the automobile engine. In the air conditioning system, the micromotor shaft can be used to control the position and size of air conditioning outlet to meet the needs of passengers; In the seat adjustment system, the micromotor shaft can be used to control the front and back of the seat, up and down, tilt and other movements, so as to facilitate passengers to get a more comfortable sitting position.In addition, the micromotor shaft can also be used to control the automatic opening of the trunk, automatic locking and other functions in the car, making the use of the car more convenient and safe.

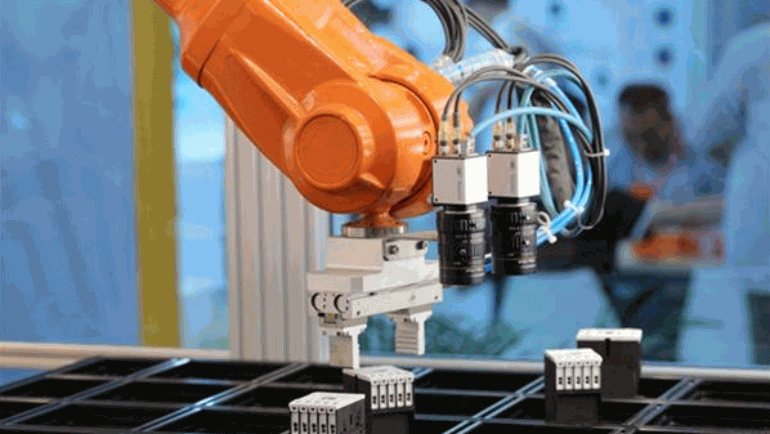

View MoreThe role of the micro-motor shaft in industrial automation is very important, mainly reflected in the following aspects: 1. Motion control: The micro-motor shaft can achieve precise motion control through sophisticated motion control technology, thereby controlling the motion status of various machinery and equipment on the entire industrial automation production line. 2. Transmission function: The micro-motor shaft can be used as the core component of the transmission mechanism to convert electrical energy into motion energy, and cooperate with other machinery and equipment to complete the requirements of various production processes. 3. Detection function: Various sensors and detection devices are integrated inside the micro-motor shaft, which can monitor and feedback the motion state in real time, so as to realize the intelligent control of the entire automated production line. 4. Stability: The motion stability of the micro-motor shaft is very high, which can improve the working efficiency and production capacity of the equipment. In short, the micro-motor shaft plays an important role in industrial automation. It can not only improve production efficiency and quality, but also improve the intelligence level of the automated production line, making the production process more automated, intelligent and efficient.

View MoreThe application of micromotor shaft in medical equipment is very extensive, mainly reflected in the following aspects:1. Display and two-dimensional code scanner: micromotor shaft can be used to drive display and two-dimensional code scanner in medical equipment, providing high-precision position control and scanning accuracy to ensure the accuracy and efficiency of medical equipment.2. Syringe and pump: The micromotor shaft can be used to drive the syringe and pump in the medical equipment, accurately control the delivery and flow of the liquid medicine, and ensure the accuracy, safety and efficiency of the liquid medicine.3. Display and surgical robot: The micromotor shaft can be used to drive the display and surgical robot in medical equipment to ensure the accuracy and stability of operation and improve the accuracy and safety of surgery.In short, micromotor shaft is widely used in medical equipment, which can improve the operating accuracy and safety of medical equipment and ensure the efficiency and reliability of medical equipment.

View MoreThe application of micro-motor shafts in marine machinery is also very extensive, mainly including the following aspects: 1. Steering gear and controller: The micro-motor shaft can be used to drive the steering gear and controller, providing high-precision position control and rudder angle control to ensure the accuracy and safety of the ship. 2. Pumps and fans: Micro-motor shafts can be used to drive pumps and fans in marine machinery, precisely control the flow and pressure of liquids and gases, and ensure the stability and efficiency of the entire system. 3. Ship positioning and water outlet drive: The micro-motor shaft can be used for ship positioning and water outlet drive, providing high-precision position and angle control to ensure the navigation and safety of the ship. 4. Ship management system: The micro-motor shaft can be used to drive the ship management system, providing high-precision positioning and control to ensure the stability and efficiency of the system. To sum up, micro-motor shafts are widely used in marine machinery, which can improve the operational accuracy and safety of ships, and ensure the high efficiency and reliability of ships.

View MoreMicro-motor shafts are commonly used in the textile industry as drive systems in textile machinery, including spinning machines, looms, spinning frames, etc. Its role mainly has the following aspects: 1. Improve the production efficiency of textile machinery: the micro-motor shaft can achieve high-efficiency production and improve production efficiency by precisely controlling the rotation speed and direction of the motor, as well as the feed speed and position of the textile machinery. 2. Improve the quality of textiles: the micro-motor shaft can realize the smooth operation of the transmission system through high-precision control of textile machinery, reduce the occurrence of fiber breakage and other adverse phenomena, and ensure the quality of textiles. 3. Reduce machine failure: The micro-motor shaft has high reliability and durability, and its drive system can greatly reduce the incidence of machine failure, thereby reducing downtime and maintenance costs in production. In short, the micro-motor shaft plays an important role in the textile industry. It can not only improve production efficiency and textile quality, but also reduce machine failure rates, thereby achieving the purpose of reducing production costs and improving production efficiency.

View MoreRecent Blog

2017 a happy ending

STFF in 2017, a total of 1.5 billion shaft production tasks have been completed .the total output is 58 million.Old cust···

Read More >

What is the future trend of the international servo system?

In recent years, there has been a wave of new and high technology transformation, which is represented by robots and art···

Read More >Keep in touch

We are looking forward to your win-win cooperation Our main goal is to provide high quality services and customer satisfaction