What is the future trend of the international servo system?

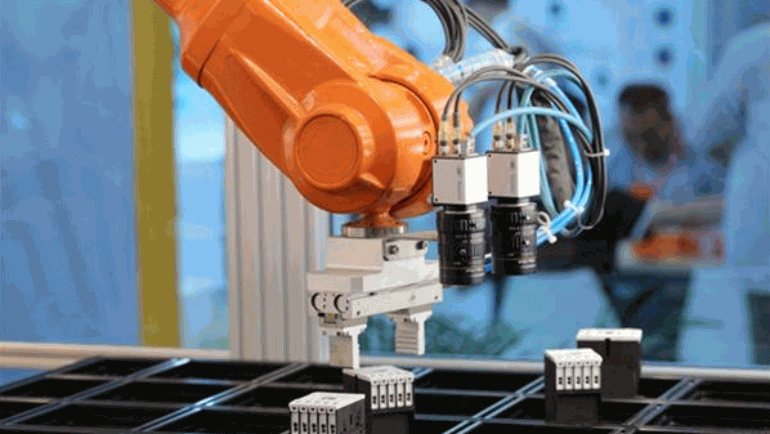

In recent years, there has been a wave of new and high technology transformation, which is represented by robots and artificial intelligence, and the application of industrial automation has been expanding.As an important part of automation, the continuous development of international servo system has greatly enhanced the technological level of global intelligent manufacturing and laid a good foundation for industrial automation.

Development of international servo system

Development and the development of the servo motor servo system closely linked, experienced three main stages: before the 1960 s, or by stepping motor driven hydraulic servo motor to power stepping motor direct drive as the center, the position of the servo system control for the open loop system.

60-70 – s of the 20th century, this phase is the birth of the dc servo motor and the era of full development, due to the dc motor has excellent performance of speed adjustment, many high-performance drive equipment adopted dc motor, servo system is a way to control also become a closed loop system by open loop system.In the application field of automation, permanent magnet direct current motor is dominant, its control circuit is simple, without excitation loss and low speed performance.

Since the 1980 s, with the development of the electromechanical integration time and the servo motor and permanent magnet structure, control technology of breakthrough in brushless dc servo motor, ac servo motor and other new type of motor.

With the development of the technical level of servo motor and the penetration of the downstream application market, the annual demand of the global servo motor is increasing rapidly.By 2014, the global demand for servo motors has reached about 28 million.

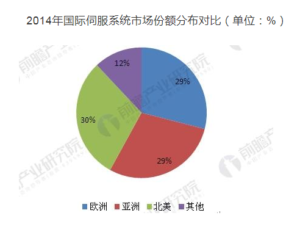

From the point of the global market, Germany, Japan, Italy, the United States is one of the largest countries share servo system application, servo motor market formed the situation of the three pillars of Europe, North America, Asia.In 2014, north American servo motor demand accounted for 30% of global demand.The European market accounted for 29%, and the region was the fastest growing market for global servo motors, with a global share of nearly 29% in 2014 and a similar share to European market share.In the background of this trend, STFF has established the servo motor shaft division, which provides high quality servo motor shaft for servo motors.The servo motor shaft factory was born.

International servo system development trend

In the future, with the continuous development of the servo system industry and the expansion of automation application, the market scale of international servo system will continue to grow.In the next five years, the global server market is expected to grow by more than 5% compound annual growth rate, and by China, India and other emerging market demand the stimulation of the engine, the market demand will reach 43 million by 2021 servo system, at the same time, the servo drive will be to develop in the direction of high power.

At the same time, the international servo system will present the following two trends.First, the policy and standards are constantly improving.International scope, the continuous development of the government and the international standard servo industry bring far-reaching influence, such as the U.S. energy bill EPactII provisions on motor system energy efficiency, American UL, NEC (NFPA) standards for safety regulations, the eu RoHS, WEEE, and CE standard of environmental and safety regulations, etc.

Second, the application scope of ac servo system is expanding.The market scope of ac servo system is expanding, and more and more replace mechanical transmission, hydraulic and pneumatic transmission system.The ac servo is continuously replacing the market share of dc servo, which leads to the total market share of dc servo in the whole servo market from less than 15% every year.Ac servo cost and size shrinking at the same time, also in eating into high-end stepper motor market, but in stepping motor itself also unceasingly to enhance their competitive ability, constantly extend the market space, so after receipt of the impact of market is expanding at the same time, just may not be ac servo so fast.

STFF has more than ten years of production experience in the motor shaft production industry. No matter how the motor industry is updated, we always insist on becoming the global motor shaft supplier.