CNC turning process specific analysis

(1) CNC turning technology first thing to consider is the rationality of the parts map. Mainly in three aspects of analysis, that is, the size of the parts on the scale method is appropriate and CNC machine tool processing requirements, analysis of node coordinates calculation and analysis of the accuracy of the parts and technical requirements.

(2) whether the dimension method on the part drawing is suitable for the processing requirements of the CNC machine, which determines the rationality of the machined parts. The dimensions of the parts are given directly under the same reference, so that the design, process, measurement and programming origin can be unified stand up. This avoids unnecessary trouble and simplifies the various programming calculations.

(3) analysis of node coordinates calculation, in the processing of parts, including manual programming and automatic programming, in the manual programming to calculate the coordinates of each node, in the automatic programming will have to define all the geometric elements. Therefore, in the analysis of the parts diagram, to analyze the calculation of node coordinates.

(4) Analysis of the accuracy and technical requirements of the parts to be processed, you want to choose a reasonable parts processing methods, clamping methods and cutting costs, etc., must analyze the specific size of parts with superb technical level. Take full account of the various possibilities, if not achieve the desired effect of the remedial measures, in the established goals to complete all the links, and timely changes in accordance with the actual situation cutting speed, in any case to ensure the quality of work, the fact is, Do not cover the truth.

Related Products

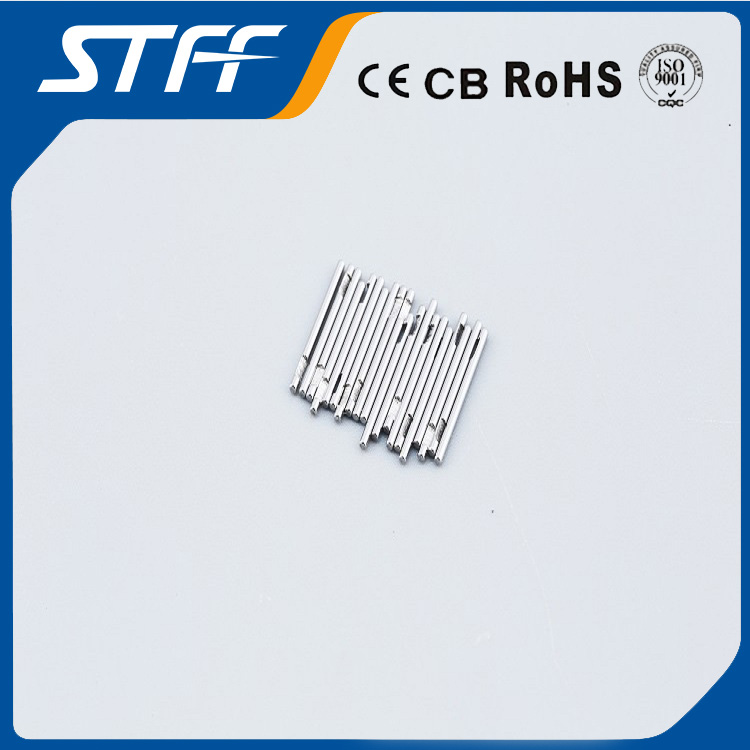

ISO factory 2mm shafts

material : SUS303 process : machining external diameter : 0.6-6.0mm overall length : 2.0-100mm tolerance : ±0.0015

Learn MoreToy motor shafts pin micro motor shaft with groove

material :DSR7B 3Cr13 4Cr13 SUS303 SUS304 SUS420F SUS420J2process :machiningexternal diameter :0.6-6.0mmoverall length :1.95-60mmtolerance :±0.0015surface hardness :HRC 20- HRC 57

Learn Moremicro motor shafts commutator shafts with groove

material : DSR7B 3Cr13 4Cr13 SUS303 SUS304 SUS420F SUS420J2 process : machining external diameter : 0.6-6.0mm overall length : 1.95-50mm tolerance : ±0.0015 surface hardness : HRC 20- HRC 57

Learn MoreVibrating motor shafts Cylindrical motor shafts Flat motor shafts

material : DSR7B 3Cr13 4Cr13 SUS303 SUS304 SUS420F SUS420J2 process : machining external diameter : 0.6-6.0mm overall length : 1.95-60mm tolerance : ±0.0015 surface hardness : HRC 20- HRC 57

Learn MoreHot 1.0 high precision micromotor shafts vibrating motor axis pin with a flat

material : SUS420F process : CNC machining external diameter : 3.175MM overall length : 55-78MM tolerance : ±0.005 surface hardness : HRC 20- HRC 57

Learn More2.0 High precision micro motor shafts vibrating motor axis micro shafts pin with a knurling Stainless steel shaft or pin with a knurling

material : SUS303 process : machining external diameter : 2.0-15.0mm overall length : 15-150mm knurling : Straight grain tolerance : ±0.05

Learn MoreHigh Precision Stainless Steel Pin Micro Motor Shaft Vibrating Motor Axis Micro Shafts 0.5mm 0.6mm 0.7mm 0.8mm 1.0-6mm

material : DSR7B 3Cr13 4Cr13 SUS303 SUS304 SUS420F SUS420J2 45steel Bearing steel process : machining external diameter : 0.6-6.0mm overall length : 1.95-40mm tolerance : ±0.001 surface hardness : HRC 20- HRC 57

Learn MoreThe factory hot sells high precision brush terminal

material : H59-1 process : CNC machining external diameter : 2.0-15.0mm overall length : 5.0-60mm tolerance : ±0.01

Learn MoreThe China factory has a custom motor linear shaft

material : 45# / 3Cr13 process : cnc machining turning external diameter : 4.0-15.0mm overall length : 20-200mm tolerance : ±0.002 surface hardness : HRC 20- HRC 57

Learn MoreThe factory sell like hot cakes linear shaft

material : 45# process : cnc machining turning external diameter : 5.0-15.0mm overall length : 50-200mm tolerance : ±0.002 surface hardness : HRC 20- HRC 57 screw thread : M6 L / R

Learn MoreHigh precision electrical shaft

material : 45# process : machining external diameter : 4.0-15.0mm overall length : 50-200mm tolerance : ±0.002 surface hardness : HRC 20- HRC 57

Learn MoreMicro Motor Shaft Supplier

material : 45# process : machining external diameter : 4.0-15.0mm overall length : 50-200mm tolerance : ±0.005 surface hardness : HRC 20- HRC 57 screw thread : M6 L / R

Learn More