Introduction to rapid cnc machining

Rapid cnc machining digest:

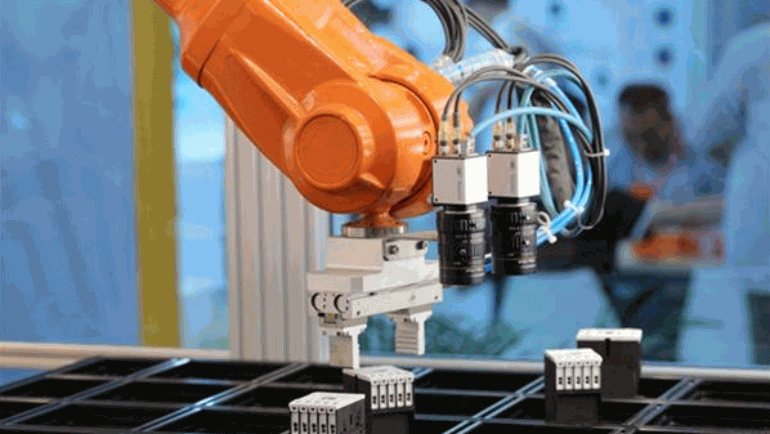

With the increasingly development of processing technology of rapid cnc machining has become the mainstream.What is the rapid cnc machining.Let me according to the characteristics of rapid cnc machining and rapid cnc machining of two aspects to do a simple elaboration.And introduced the high speed cutting technology in the aerospace, mould manufacturing, automobile manufacturing and other fields is widely used.

Although there are a lot of people talking about the rapid cnc machining (HSM), but for the definition of the term has not unified.However, may be a better method according to the phenomenon of “stability” to define rapid cnc machining.

A common definition is based on rapid cnc machining surface processing speed that the relative speed between tool and workpiece.In essence, this is a kind of restrictions on heat, because many of the cutting tool wear mechanism depends on the temperature.Using surface processing speed to define the high speed machining is quite popular with the manufacturers and researchers in metal cutting tool.In the international society for production engineering (CIRP) 1992 annual meeting, H.Schulz and T.Moriwaki in a paper entitled “the rapid cnc machining” classic in the paper, based on the surface of processing speed, made a similar to the chart below, shows the conventional processing, the transition zone and high speed machining speed range.Surface processing speed v (m/min) determined by formula v = WDN (including: d is the diameter of the milling cutter or artifacts, n for spindle speed).The processing speed of high-speed machining of p (1000 m/min), for example, a 25 ram cutter diameter, to 15000 – m’s rotate speed, the surface processing speed is 1177.5 m/rain

Another definition of rapid cnc machining method associated with the emergence of the phenomenon of “stability”.When the main blade frequency changes to the inherent frequency of a large part of, will appear “stable waveform.When low speed processing, the choice of the spindle speed does not significantly change the machine dynamic performance.The stability limit – when the cutting depth exceeds the value chatter occurs – seems to be a constant.When the main blade frequency changes to account for the inherent frequency of a considerable part of the (such as l, 4, 1/2 or 1/3, 1/1), by selecting the correct spindle speed, can easily will increase 2 times or more metal removal rate.For example, when using a double edge milling cutter with maximum flexibility inherent master frequency (1200 Hz) milling of aluminum alloy, the spindle speed is 1200 x60 + 2 = 36000 RPM, the stable waveform effect is strongest.Other major region will appear in the speed of 18 respectively, O00rpm, 12000 RPM and 9000 RPM.To have lower inherent in the main frequency of the cutting tool system, a “stable waveform” effect of spindle speed could be greatly reduced.When using a 6 milling cutter to the inherent master frequency of 250 hz milling of titanium alloy, the most stable processing area will appear in the spindle speed is 250 x60 + 6 = 2500 RPM, according to the dynamic point of view, and the speed is still belongs to the category of high speed machining.

rapid cnc machining technology represents the development direction of machining, and gradually become the mainstream of machining technology.Due to the application of high speed cutting technology can significantly improve the machining efficiency and machining precision, reduce the cutting force, reducing cutting heat effect on the artifacts, implementation process intensification, etc., so has been in the aerospace, mould manufacturing, automobile manufacturing and other fields is widely used, and achieved good economic benefit.In the forming of modern mold manufacturing, due to the increasingly complex mold profile design, the increasing proportion of free-form surface, thus puts forward higher requirements on mould processing technology, which should not only ensure the manufacture of high precision and surface quality, and to pursue the processing surface is beautiful.Along with the continuously go deep into the research of high speed machining technology, especially in machine tools, CNC system, cutting tool system, CAD/CAM software under the impetus of the development of related technologies, such as rapid cnc machining technology has been increasingly used in mold manufacturing and processing.High speed machining technology has great influence on the mold processing technology, changed the traditional mould processing using the “annealing a milling processing, heat treatment, grinding” or “a manual grinding, polishing edm” long and complicated process, such as high-speed cutting and even can be used all the original process.High speed machining technology can be applied to a hardened mold cavity directly processing the especially for semi-finishing and finishing Dum) gb, in EDM electrode processing, rapid sample manufacture, etc are also widely used.A large number of production practice showed that the application of high speed cutting technology can save about 80% of the manual grinding in mold after processing time, save the processing costs nearly 30%, mold surface machining precision can reach the I m, about double knives cutting efficiency can be improved.