Analysis and forecast of the development prospect of China’s micro motor industry in 2017

1.Micro electric motor is one of the most important basic motor parts for industrial automation, office automation and home automation.It has a very wide range of application fields, household appliances, automobiles, electric cars, audio-visual, communications, computers, robotics, military and aerospace, industrial machinery, automation etc is inseparable from the use of micro &special motor technology.With the application of micro motor in these fields, the global demand for micro motor is increasing rapidly.In 2010, the global demand for the micro – motor market reached 14 billion, and will continue to grow at around 15% a year.In economically developed countries and regions, the people’s standard of living is higher, per household appliances, automobiles, computers, etc of the large number of products applied micro &special motor, micro &special motor home ownership for an average of 80-130;In China, the average number of micro electric household in the large cities is only 20-40, which is far lower than that of developed countries, and the development space is huge.China’s micro electric motor industry has benefited from the rapid economic development, and the market sales have maintained a high growth momentum.According to the statistics of the national bureau of statistics, the sales revenue of China’s micro-motor manufacturing industry rose from 75628 million yuan in 2007 to 224.86 billion yuan in 2014, and the annual compound growth rate reached 16.8%.

2.The main application domain of micro motor is the highest in the distribution of household appliances, automobiles and information processing machines.The company produces the commutator machine at high speed micro &special motor mainly used in vacuum cleaners, garden tools, cleaning machine, auto parts and other downstream products, the future is expected to washing machine, oil absorption, air conditioning and other fields.

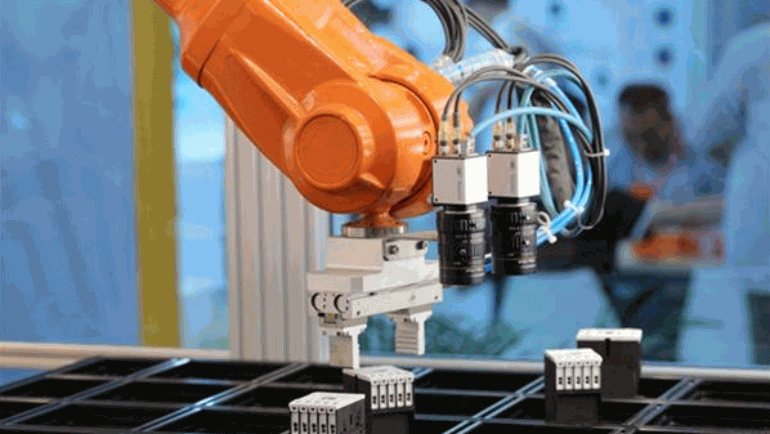

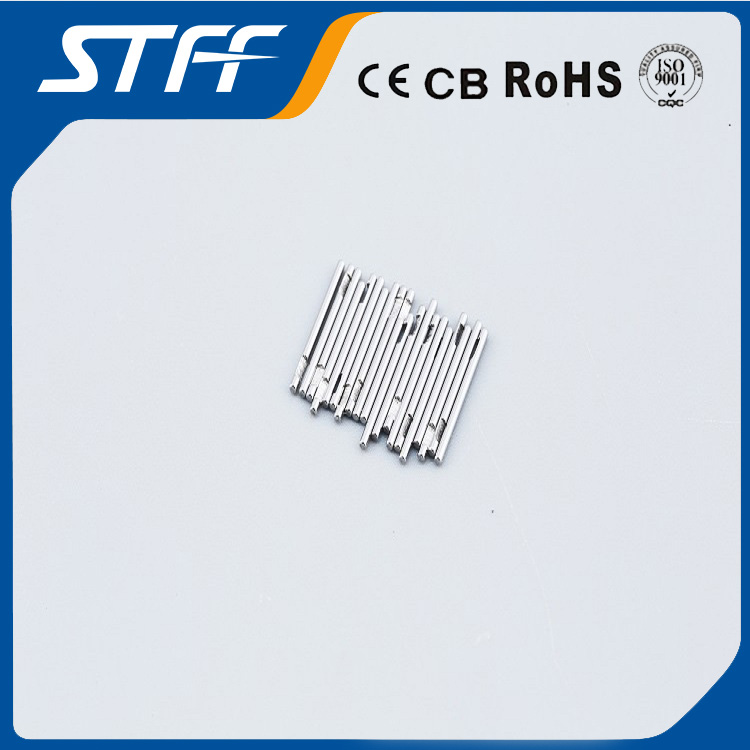

STFF, founded in 2005, is a company that provides micro electric motor shaft for micro motor manufacturers,with the increasing demand of micro electric motor shaft,The STFF plant has invested huge sums of money to transform smart factories,improve product quality and market competitiveness,the plant can produce 200 million micro electric motor shaft,Provide high quality micro electric motor shaft for all micro electric motor manufacturers.