Advantages of CNC vertical turning center

CNC vertical turning center in the use of time, not only can make the production and processing more efficient, and can make the stability of the machining processing can be better to enhance the overall simplification of the overall processing and production complexity, and for the production efficiency Said to be able to achieve higher standards, so you can in the shortest possible time to achieve higher production efficiency, to the enterprise machining processing and production has brought absolute protection, is currently recognized by many businesses, but also in the machining processing of production Will not be any error.

Through the use of CNC vertical turning center for processing and production, can make the overall production process to simplify, and in use when the processing accuracy can be improved to avoid the emergence of a variety of complex error values, and the error in the cumulative The process will also be prone to particularly serious impact, both affect the overall production accuracy standards, but also to a certain extent, may also waste raw materials, and in the process of sales will be a lot of problems, so in order to meet the public The user needs to use, in the production process must achieve a higher accuracy. In the choice of mechanical equipment also need to pay attention to very high performance.

In the CNC turning production and machining processing technology also need to achieve a higher process standards, naturally you can make the use of more perfect effect, can shorten the overall manufacturing process chain, when we do machining processing production, do not need to put too much Of the staff to carry out care, so in the production and processing management, the overall cost of capital will be a reasonable control, and now in the process of production and production, there are online intelligent monitoring system, any problems can be carried out directly Alarm, the staff can be the first time to understand the situation.

Related Products

ISO factory 2mm shafts

material : SUS303 process : machining external diameter : 0.6-6.0mm overall length : 2.0-100mm tolerance : ±0.0015

Learn MoreToy motor shafts pin micro motor shaft with groove

material :DSR7B 3Cr13 4Cr13 SUS303 SUS304 SUS420F SUS420J2process :machiningexternal diameter :0.6-6.0mmoverall length :1.95-60mmtolerance :±0.0015surface hardness :HRC 20- HRC 57

Learn Moremicro motor shafts commutator shafts with groove

material : DSR7B 3Cr13 4Cr13 SUS303 SUS304 SUS420F SUS420J2 process : machining external diameter : 0.6-6.0mm overall length : 1.95-50mm tolerance : ±0.0015 surface hardness : HRC 20- HRC 57

Learn MoreVibrating motor shafts Cylindrical motor shafts Flat motor shafts

material : DSR7B 3Cr13 4Cr13 SUS303 SUS304 SUS420F SUS420J2 process : machining external diameter : 0.6-6.0mm overall length : 1.95-60mm tolerance : ±0.0015 surface hardness : HRC 20- HRC 57

Learn MoreHot 1.0 high precision micromotor shafts vibrating motor axis pin with a flat

material : SUS420F process : CNC machining external diameter : 3.175MM overall length : 55-78MM tolerance : ±0.005 surface hardness : HRC 20- HRC 57

Learn More2.0 High precision micro motor shafts vibrating motor axis micro shafts pin with a knurling Stainless steel shaft or pin with a knurling

material : SUS303 process : machining external diameter : 2.0-15.0mm overall length : 15-150mm knurling : Straight grain tolerance : ±0.05

Learn MoreHigh Precision Stainless Steel Pin Micro Motor Shaft Vibrating Motor Axis Micro Shafts 0.5mm 0.6mm 0.7mm 0.8mm 1.0-6mm

material : DSR7B 3Cr13 4Cr13 SUS303 SUS304 SUS420F SUS420J2 45steel Bearing steel process : machining external diameter : 0.6-6.0mm overall length : 1.95-40mm tolerance : ±0.001 surface hardness : HRC 20- HRC 57

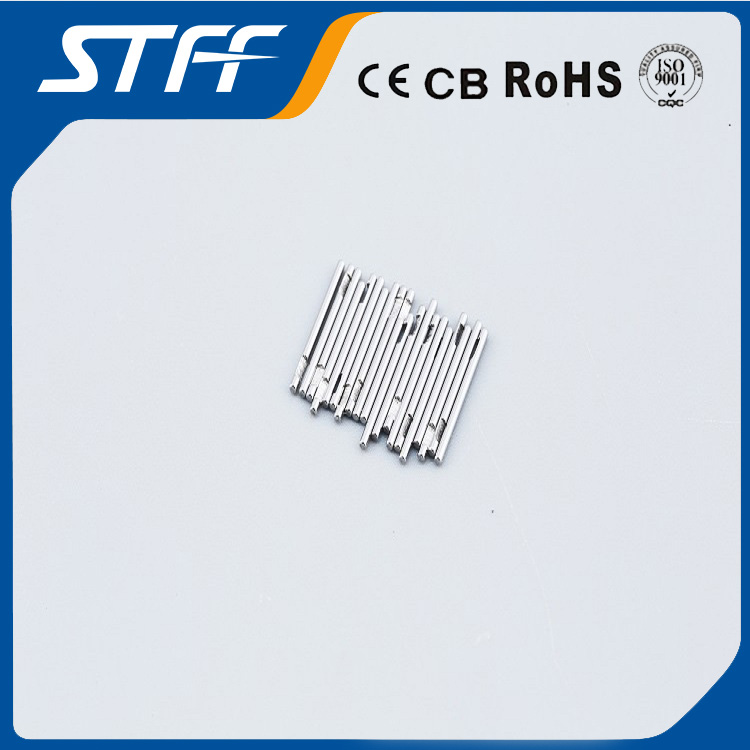

Learn MoreThe factory hot sells high precision brush terminal

material : H59-1 process : CNC machining external diameter : 2.0-15.0mm overall length : 5.0-60mm tolerance : ±0.01

Learn MoreThe China factory has a custom motor linear shaft

material : 45# / 3Cr13 process : cnc machining turning external diameter : 4.0-15.0mm overall length : 20-200mm tolerance : ±0.002 surface hardness : HRC 20- HRC 57

Learn MoreThe factory sell like hot cakes linear shaft

material : 45# process : cnc machining turning external diameter : 5.0-15.0mm overall length : 50-200mm tolerance : ±0.002 surface hardness : HRC 20- HRC 57 screw thread : M6 L / R

Learn MoreHigh precision electrical shaft

material : 45# process : machining external diameter : 4.0-15.0mm overall length : 50-200mm tolerance : ±0.002 surface hardness : HRC 20- HRC 57

Learn MoreMicro Motor Shaft Supplier

material : 45# process : machining external diameter : 4.0-15.0mm overall length : 50-200mm tolerance : ±0.005 surface hardness : HRC 20- HRC 57 screw thread : M6 L / R

Learn More