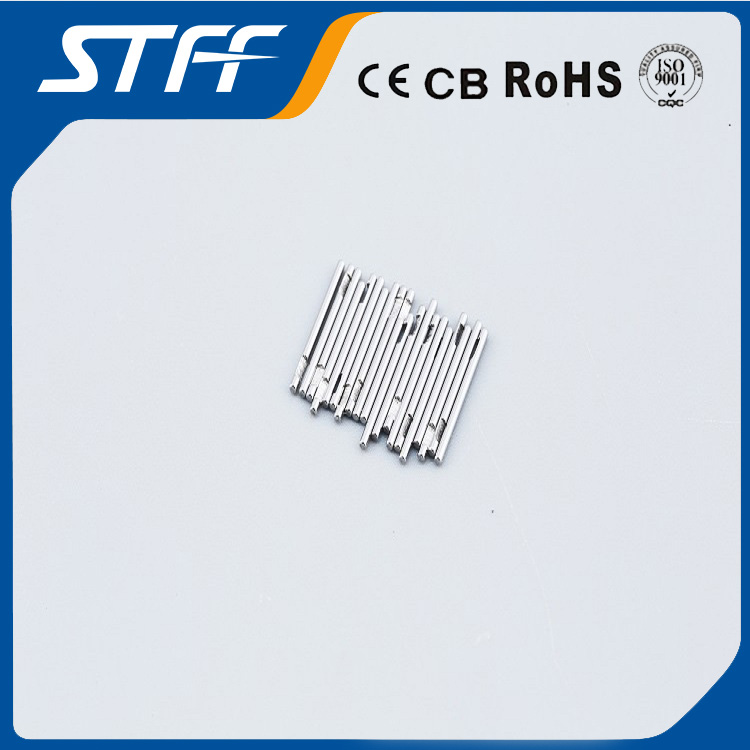

How to choose the best motor shaft material

First let’s talk about some of the most commonly used materials on the motor shaft material

1:3Cr13 2:4Cr13 3:DSR7B 4:45# 5:Gcr15

3Cr13:

Standard:GB/T1220-1992,martensite type stainless steel,this steel has good machining properties,after heat treatment (quenching tempering), it has good corrosion resistance and high strength and wear resistance,It is suitable for high load, high wear resistance and electric motor parts under the action of corrosive medium.

Product attributes

density :7.75g/cm3

In the United States is called:420S45

In the France is called:Z30C13

Principal component

C :0.26~0.35

Si:≤1.00

Mn:≤1.00

S :≤0.030

P :≤0.035

Cr:12.00~14.00

Ni:≤0.60%

mechanical property

σb (MPa):≥735

σ0.2 (MPa):≥540

δ5 (%):≥12

ψ (%):≥40

Akv (J):≥24

hardness :annealing,≤235HB;Quenching tempering,≥217HB

Due to its excellent processing performance, it will not rust, and its price is low. It is widely used in micro motor.

4Cr13

40Cr13 (old :4Cr13) Standard:GB/T 1220-1992

A stainless steel material with high hardness and high wear resistance.

In the Germany is called:X40Cr13

In the France is called: Z40C14

characteristic

After quenching is higher than 3Cr13 hardness and good corrosion resistance.It is used for high hardness and high wear resistance, such as hot oil pump, valve plate, valve bearing, medical instrument, motor accessories and so on.

45#

China:45#

Japan:S45C/S48C

Germany:C45

England:IC45/080A47

France AFNOR:CC45

France NF :C45

USA AISI/SAE:1045

Principal component

C:0.42~0.50%

Si:0.17~0.37%

Mn:0.50~0.80%

P: ≤0.035%

S: ≤0.035%

Cr:≤0.25%

Ni:≤0.25%

Cu:≤0.25%[1]

mechanical property

density :7.85g/cm3

Heat treatment requirement

- The adjustment hardness is between HRC20 ~ HRC30

- The hardness of quenching is between HRC55 ~ 58 and the limit value can be up to HRC62

-

It should be used for 15-20 days because of the aging treatment to stabilize the steel performance.

The highest hardness of practical application is HRC55 (high-frequency quenching HRC58)

45# steel for high quality carbon structure steel, hardness is not high and easy to be machined, the mold is often used to make the template, the tip, the guide column, but must heat treatment.

The hardness is greater than HRC55 (up to HRC62) before quenching.The highest hardness of practical application is HRC55 (high frequency quenching HRC58).

Do not use the heat treatment process of carburizing and quenching.

The parts have good comprehensive mechanical properties and are widely used in various important structural parts, especially those of connecting rods, bolts, gears and shafts which are working in the alternating load.But the surface hardness is lower, not wear-resisting.The surface hardness of the parts can be improved by improving the surface quenching.

DSR7B

Japan datong stainless steel,relative to sus420j2 (3Cr13) hardness, corrosion resistance is high.

GCr15

It refers to a high-carbon chromium bearing steel with low alloy content, which has high hardness, uniform structure, good wear resistance and high contact fatigue property after tempered and low temperature tempering.

The application field has machine tool ball screw rod, nozzle nozzle of turbine jet engine, plunger, valve, electric motor parts, etc.

Principal component

C:0.95-1.05

Mn:0.20-0.40

Si:0.15-0.35

S:≤0.020

P:≤0.027

Cr:1.30-1.65

Mo:≤0.10

Ni:≤0.30

Cu:≤0.25

Ni+Cu≤0.50

mechanical property

(HRC):25.8

(MPa):861.3

(MPa):518.42

(%):27.95

(MPa):1821.61