How to reduce the electric motor shaft design cost and time

The motor is one of the most widely used equipment in the various sectors of the national economy. The performance of the motor shaft has a great influence on the motor performance and is a key component of the motor. The structure of the motor shaft is mainly composed of several pieces (6 ~ 8) of the ribs welded together on the spindle, the silicon and the coil around the ribs, the use of magnetic field to produce current to work. In the work of the motor, the combination of the ribs and the shaft due to the periodic action of the electromagnetic force there is a large stress concentration, coupled with the conventional design of the shaft and the general process defects, will produce fatigue cracks, and ultimately lead to parts Fracture failure. Therefore, the success of the motor design depends to a certain extent on the merits of the motor shaft design. In the past design, according to the performance requirements of the motor, according to the experience of the design of the motor shaft prototype, after the test to obtain the motor shaft performance; when the motor shaft performance does not meet the design requirements, the need to adjust the motor shaft to adjust the corresponding structural parameters, And then re-test.

electromagnetic force there is a large stress concentration, coupled with the conventional design of the shaft and the general process defects, will produce fatigue cracks, and ultimately lead to parts Fracture failure. Therefore, the success of the motor design depends to a certain extent on the merits of the motor shaft design. In the past design, according to the performance requirements of the motor, according to the experience of the design of the motor shaft prototype, after the test to obtain the motor shaft performance; when the motor shaft performance does not meet the design requirements, the need to adjust the motor shaft to adjust the corresponding structural parameters, And then re-test.

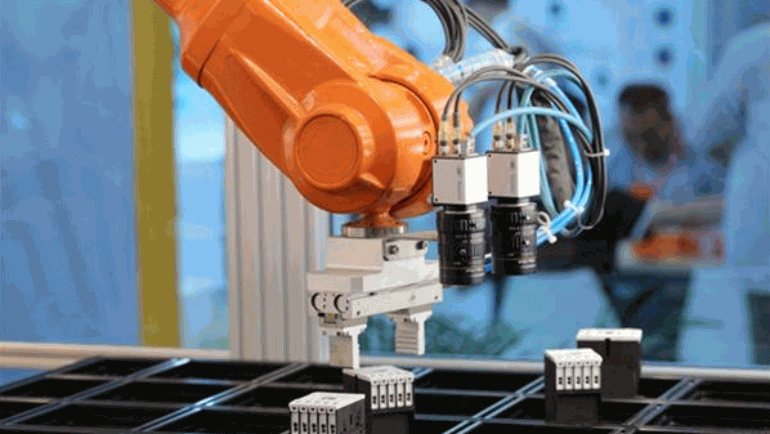

This repeated cycle of the process to make the design cycle is long, high cost of equipment. In order to solve this problem, the author uses the CAE software provided by MSC to analyze the stress distribution and displacement deformation of the current motor shaft, and comprehensively optimize the structural parameters and working performance of the motor shaft. Firstly, the finite element analysis model is generated by using PRO-E and then imported into ANSYS. The stress distribution is obtained by ANSYS, and then the structural parameters are adjusted by using the optimized design technique to reduce the stress concentration. Motor shaft structure optimization at the same time, so that the motor performance to achieve the best, so the design cycle is greatly shortened, the design cost is significantly reduced, the economic benefits are obvious.

STFF has been engaged in manufacturing motor shaft and production for more than 20 years,We can recommend the motor shaft for our clients to be more suitable for their product features.Our Heat Treating and forging facility under one roof. Extensive quality assurance department equipped with CMM machine, CNC gear tester, spectrographic, metallographic and magnaflux equipment. All design and production of tools dies and molds are done in house. We use the latest technology such as CAD/CAM to assist in the design and manufacturing process.so we can save 10-15% off existing manufacturing costs, giving our clients a highly competitive price without compromising the part integrity.