The current situation of micro motors

China’s micro-motor industry was founded in the late 1950s, from the beginning to meet the needs of national defense weapons and equipment, has gone through the imitation, self-design and research and development stage, has been more than 40 years of development history, has formed product development, And key parts, key materials, special manufacturing equipment, test equipment supporting a complete industrial system. High-speed micro-motors, such as precision brushless motors, high-speed synchronous motors, high-precision stepper motors, chip winding brushless motors, high-performance servo motors and new principles of new structure of the ultrasonic motor has not yet formed a commercial or mass production capacity The So the domestic high-precision micro-motor also rely on imports. According to customs statistics, the average annual consumption of 1995 to 2000 increased by 26.9%, while in 2001 increased by 4.81%, also reached 1.197 billion US dollars.

According to statistics, China’s micro-motor production and supporting manufacturers in more than 1,000, employing more than 10 million people, industrial output value of more than 10 billion yuan. Micro-motor industry has become a national economy and national defense modernization in the indispensable of a basic product industry. Japan is the world’s largest manufacturer of micro-motor, in 1996 its output reached 2.3 billion units, exports amounted to 1.6 billion units in 2000 its output fell to 1.7 billion units,the output value fell to 67.33 billion yen, about 10 years ago Japan’s micro-motor output value of half. Japan Mabuchi Motor Company is the world’s largest micro-motor manufacturer, which produces more than half of the world’s DC motor market products, in China and Taiwan Province, Malaysia, Vietnam and other places are equipped with production plants, the company’s DC motors around the world Integrated production capacity has reached 1.5 billion units.

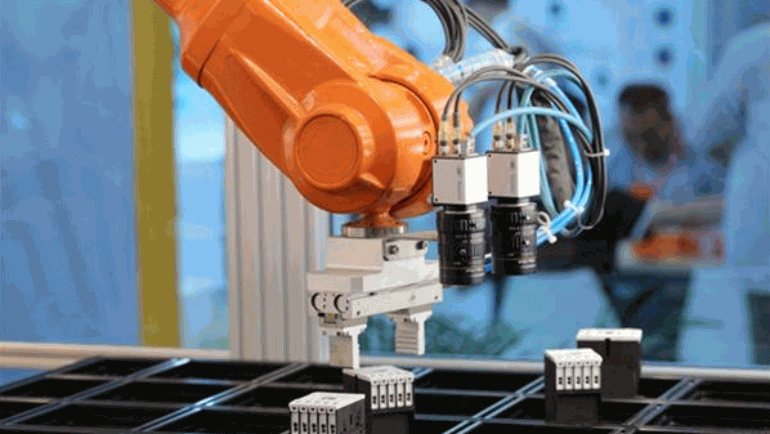

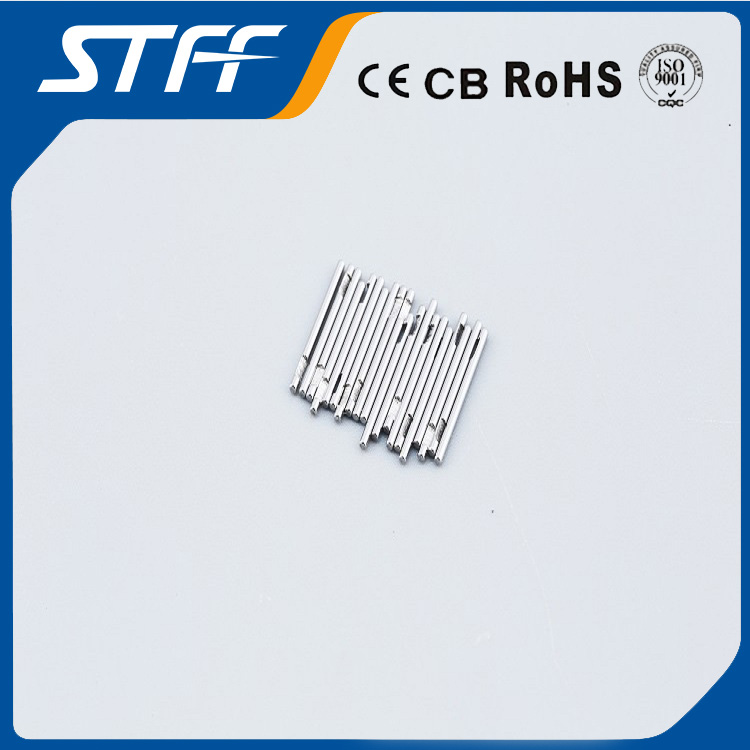

Because of Japan’s leading position in magnetic materials, electronic control and production processes, it is not only in the production of micro-motor in the world’s hegemony, in the field of technology is also the forefront of the world, its micro-motor products with large torque, small Size, high control accuracy, low power consumption, long life and low cost competitive advantage. In view of the economic benefits, the organization of micro-motor production is generally mass production, but the micro-motor shaft processing technology requirements are relatively high, but also because of its smaller size, in the processing of its implementation of the folder is difficult, Technical requirements, the milling and grinding of the shoulder surface of the shaft end, because of the size and location accuracy requirements are higher, with the general clamping method is not easy to guarantee.Therefore, the design and manufacture of clamping easy, reliable and efficient milling (or Grinding) fixture is an important guarantee for mass production of micro-motor shafts.